The different ways of

quality assurance

BBS’ highly sensitive leak detection and sniffing systems ensure that components assembled by our sophisticated manufacturing methods are leak-proof and sealed.

We analyze customer specifications and offer various methods to connect the leak detection system to other production equipment, from fully or semi-automated systems to a manual/batch version. No matter what your application or industry is, our integrated manufacturing and testing solutions will meet your requirements.

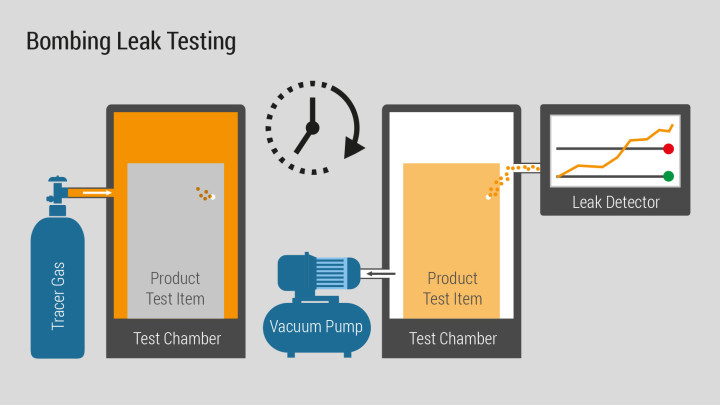

The method is used for products that cannot be connected directly to a leak detector. The product is placed in a chamber containing pressurized helium. The helium penetrates into the product. The actual test then takes place in the vacuum chamber, to which a helium detector is connected.

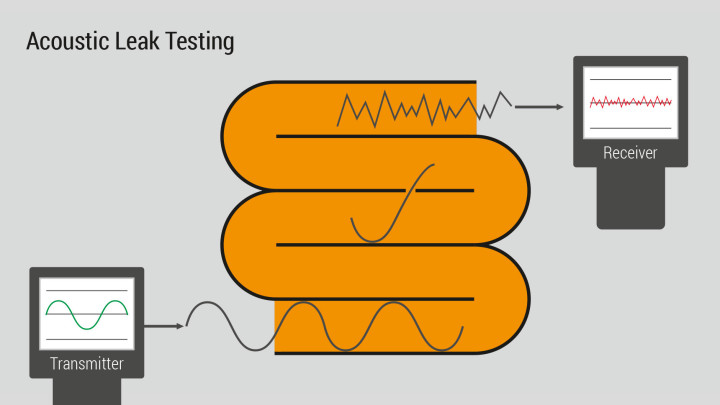

The test method is preferably used for pipe systems that cannot be accessed directly, for example because they are installed in a housing. Sound waves are sent through the test item by means of a transmitter. The sound waves recorded by the receiver are analyzed for characteristic changes in order to identify leaks.

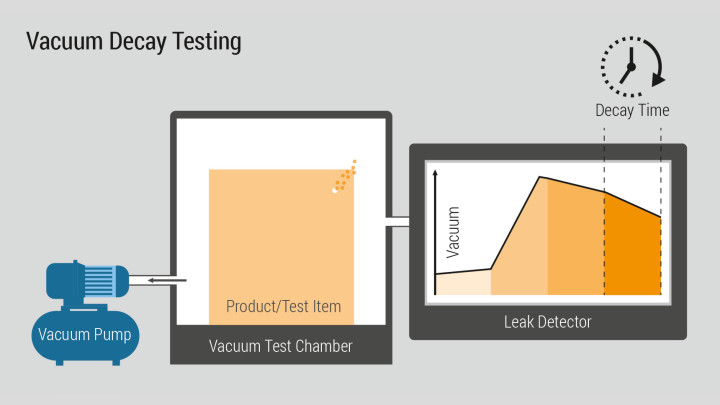

The test is an efficient test method for detecting very small leaks. The test item is located in a vacuum test chamber. The connected detector measures the vacuum level in the chamber over a certain period of time and determines the change of the vacuum level in case of a leak in the test item.

Are you interested

in professional leak detection system for your application?