Product innovation

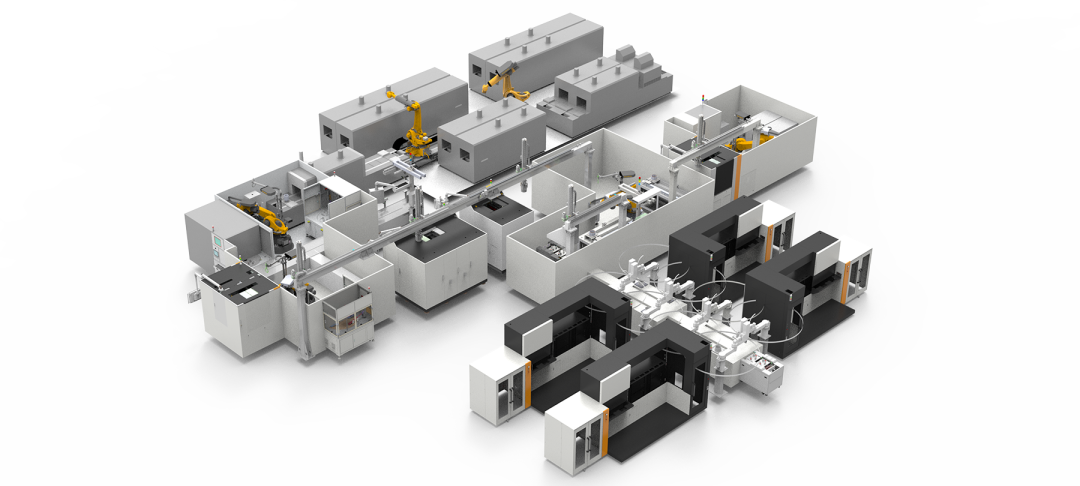

BBS China has developed a highly efficient, modular and yet highly flexible hairpin assembly system for the manufacture of electric motor stators.

Hairpin technology is of fundamental importance in the production of drives in the e-mobility sector (passenger vehicles, commercial vehicles). The new system complements the technology and product range of BBS with this important future technology. It comprises the complete process chain:

- Forming

- Widening

- Twisting

- Welding - Cutting

The BBS Hairpin assembly system is characterized by very high reliability, high output/productivity and a lean design principle. The modular design also improves scalability, allowing an existing system to grow gradually with increasing requirements for quantities and/or cycle times and/or type variance. For the realization, the BBS specialists in China have analyzed the required processes in detail in order to realize significant improvements at many points. Some of them have been applied for a patent and therefore represent unique selling propositions of the new BBS system.

As a result, the overall quality of the manufactured products is increasing.

The new system is initially designed as a laboratory application with the highest possible flexibility. Customer applications, which have already been designed to meet specific customer requirements, deliver convincing results, record-breaking cycle times and pass the highest quality requirements.

Interested? Contact us directly Contact