The most sensitive way

to detect leaks

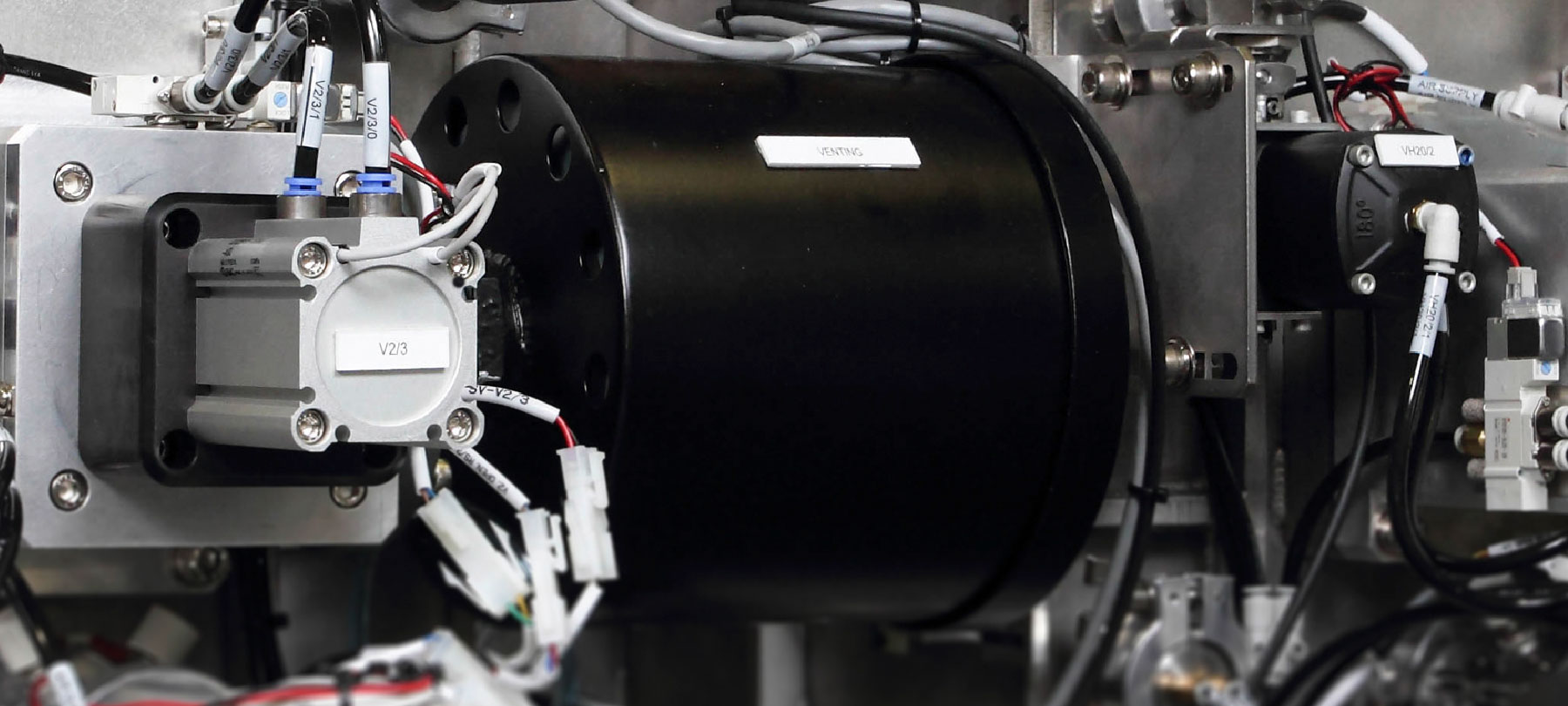

Helium leak detection systems (HLDS) are most sensitive. Our helium leak detection systems check parts and devices for the smallest flaw. They offer the perfect combination of highly advanced leak detection features plus uncompromised industrial flexibility and durability for high-vacuum applications.

The advantages of the BBS-HLDS, whether integrated into an assembly line or as a stand-alone unit, lead to faster test and assembly cycles, higher quality levels, and better process reliability — improving product quality.

Why do we use helium to locate leaks? Helium has many advantages. It occurs only in low concentrations in the ambient air and can easily be detected. Helium is non-toxic and does not react with other materials. The small atomic radius enables quick tests and the detection of even the smallest leaks. Additionally, our special helium recovery systems help to reduce emissions and costs during production.

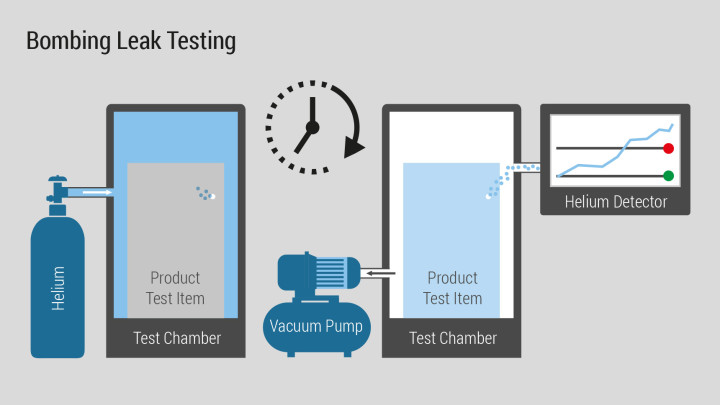

The method is used for products that cannot be connected directly to a leak detector. The product is placed in a chamber containing pressurized helium. The helium penetrates into the product. The actual test then takes place in the vacuum chamber, to which a helium detector is connected.

Are you interested

in professional leak detection system for your application?