Classic Winding Technology for Rotors and Stators

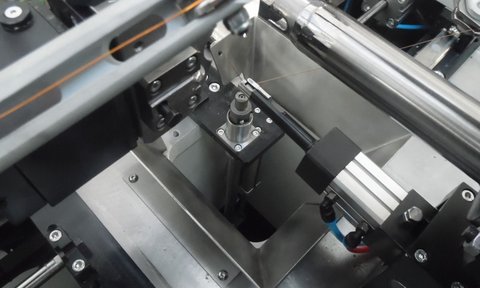

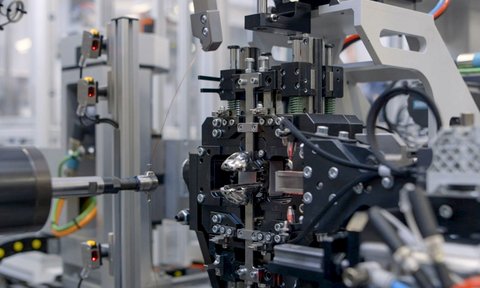

Flyer winding is a proven basic technology in the production of electric motors and is used for winding rotors and also for stators for external rotors.

In this process, the flyer turns around the product clamped in the winding tool, winding the wire from the outside. The process permits high speeds and thus ensures short process times. In addition, the machine structures, with this comparatively simple technology, are inexpensive to realize.

Due to their special design, BBS flyer winding systems, including the complete monitoring of the set-up condition, are more flexible than other technically comparable systems.

BBS machines can, for example, be equipped with only one flyer assembly for odd pole numbers or combine both concepts in one and the same machine.

Features

- Direct winding of universal motor rotors and stators of outside running motors.

- Wide range of wire diameter

- Double flyer machines, also combinable with commutator fusing on board

- Wire cutting and ripping available

- Multi-pole winding possible

- Fast cycle times through hooking plates for commutator hooking

Typical products where flyer winding is used

- Rotors for power tools

- Auxiliary engines in vehicles (ABS, power windows, seat adjustment, sunroof, etc.)

- Driving motors for washing machines

- Universal motors

- Vacuum cleaner motors

- Electric door drives

Facts about Flyer Winding

- Classic technology for electric motors e.g. in automotive appliances

- Cycle times under 6 sec.

- Type changeover/ retoolingin less than 3 minutes (comparable conventional systems: about 1h for retooling)

- Wire diameter 0,05 – 1,6 mm

Our Advantages

- Wide experience and various product range

- Global footprint of BBS

- Multilingualism of employees

- Tailored, customer-oriented solutions

- Optimized build times with 100% monitoring, reliability, quality

- Global project management and service support

- A key account team conducts each project

Downloads

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB