Multi Parts Winding at the Same Time

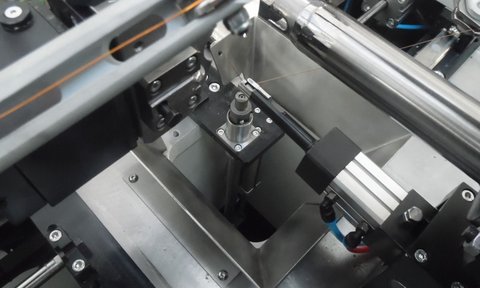

Needle winding is the process of choice for the production of internally or externally wound stators or rotors with a complex winding scheme and pole chains (see Singletooth Winding).

During the needle winding process, the needle (nozzle) that feeds the wire is moved horizontally or vertically along the pole. It thereby "circles" the pole and winds it.

In terms of the products and processes to be handled, this method offers a comparatively high degree of flexibility compared to others. The needle winding machines from BBS are able to process several different products simultaneously in one and the same machine. They achieve very high operating speeds by exploiting the physical possibilities without negative effects on process reliability.

BBS provides a wide variety of needle winding machines required for special products, e.g. for winding 2-pole stators or cam-operated winding machines where several needles can be used simultaneously to enable maximum throughput.

Features

- Flexibility (internal and external rotor)

- Multi parts winding at same time

- Freely programmable

- Wire layering

- Freely programmable contacting / wire termination (teach process)

- High filling factors despite required space for needle

- Large wire diameter range

- Freely selectable wire connections even on the lower side of stator

- Low tooling costs

Typical products where Needle Winding is used

- Pump drives

- Fans

- Power steering, servo motors

- various brushless motors

- Professional food processors

- Professional power tools

- Coolant pumps

- Heating pumps

- Vacuum pumps

- Oil pumps

- Roller shutter drives

- Wheelchair drives

- Dental drill

Facts about Needle Winding

Vertical Needle Winding

- High winding speed, up to 600 rpm

- Several different stator types and winding patterns to be wound at the same time (exclusively by BBS Winding)

- Tool freetype change over and also fully automatic type changeover

- Optional: Automatic tooling check > impossible to use wrong settings

- Wire diameter 0,1 – 1,8 mm

Cam Driven Needle Winding

- Special type of needle winding process

- For high quanitities

- Low variance

- Stroke not through servomotors but through mechanically connected cams

Our Advantages

- Wide experience and various product range

- Global footprint of BBS

- Multilingualism of employees

- Tailored, customer-oriented solutions

- Optimized build times with 100% monitoring, reliability, quality

- Global project management and service support

- A key account team conducts each project

Downloads

HEKUdish compact

PDF / 475.25 kB

HEKUdish compact

PDF / 475.25 kB

HEKUdish next Gen

PDF / 621.38 kB

HEKUdish next Gen

PDF / 621.38 kB

HEKUdish compact

PDF / 475.25 kB

HEKUdish compact

PDF / 475.25 kB

Datasheet HEKUdish next Gen

PDF / 621.38 kB

Datasheet HEKUdish next Gen

PDF / 621.38 kB